Opinions about us

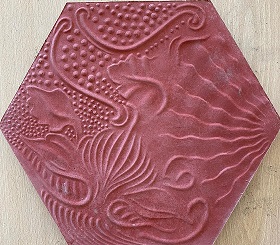

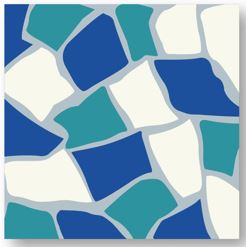

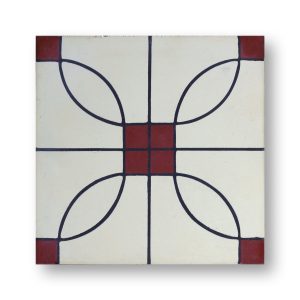

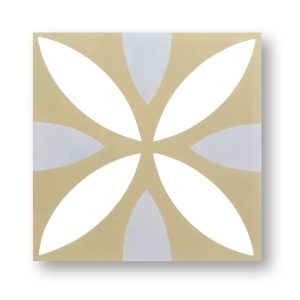

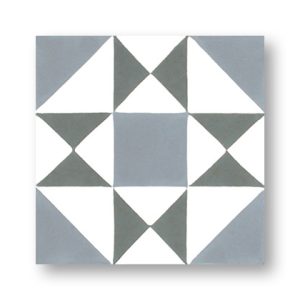

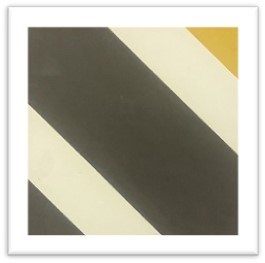

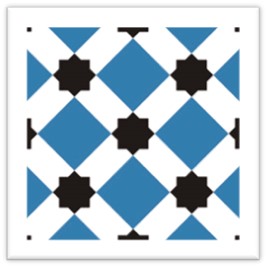

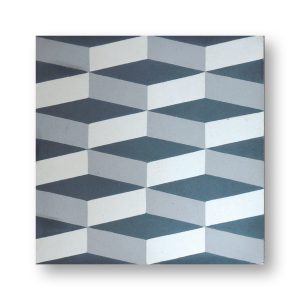

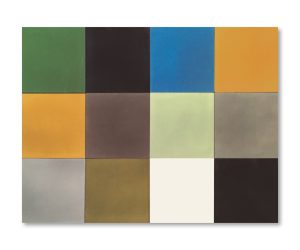

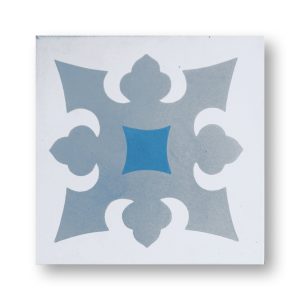

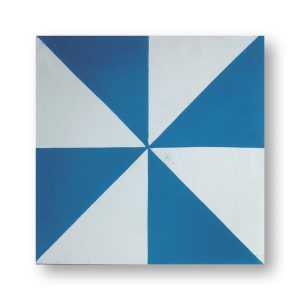

Trustindex verifica que la fuente original de la reseña sea Google. Les rajoles hidràliques Torra són precioses, m’agraden moltissim. Ja estan instalades. També vaig adquirit els productes Torra de neteja i impermeabilització pero encara no els hem posat. Durant el procés de compra em va atendre la Núria i es va ocupar del tot el que li demanava molt bé. Em vaig sentir escoltada i molt ben atesa. Gràcies NúriaTrustindex verifica que la fuente original de la reseña sea Google. Es un placer acariciar ese producto fabricado con tanto amor y dedicación. Cada una de sus baldosas vibra en humanidad, un placer y un privilegio disfrutar de productos con historia que se siguen fabricando siguiendo procesos 100% artesanos.Trustindex verifica que la fuente original de la reseña sea Google. Excelente servicio, baldosas de cemento de primera calidad, de diseño intemporal, con consejos y productos para limpieza e impermeabilización de las mismas. Absolumente recomendable. Y Nuria, en la tienda de Barcelona es de una gentileza y amabilidad incomparables. Todo de 10 con nota. Muchas gracias !Trustindex verifica que la fuente original de la reseña sea Google. Encontramos Mosaics Torra por google y qué buen encuentro. La fábrica tiene una extensa exposición y el personal un gran conocimiento de sus maravillosas baldosas hidráulicas, a cuál más bonita. Y en stock! Servicio amable y honesto. Un 10. GraciasTrustindex verifica que la fuente original de la reseña sea Google. Des del meu punt de vista excel·lent direcció artística, i amb un tracte honest que agraeixo especialment. Feia molt que buscava un disseny hidràulic per una estància i res no em feia el pes, aquí n'he trobat molts que m'han fet dubtar fins l'últim dia! Molt content del disseny que m'he endut a casa, encara es veu millor a les mans!Trustindex verifica que la fuente original de la reseña sea Google. Bien asesorado con un trato muy profesional y material de alta calidad. El surtido es espectacular con un servicio rapido. Volveré para próximas reformas. GraciasTrustindex verifica que la fuente original de la reseña sea Google. Varem anar a la seva botiga del carrer Deu i Mata de Barcelona i tot fantastic, tant l’atencio rebuda de la Nuria i la Montse com del servei, i per descomptat del mosaic hidráulic, doncs vaig fer la comanda i amb 48 horas tenia tota la comanda a casa meva, cal remarcar tambe el suport tecnic que ha tingut el meu col-locador per part de la fabrica que li van ser molt utils per l’instalacio del mosaic , us passo algunes fotos de com ens ha quedat tot. Molt recomanableTrustindex verifica que la fuente original de la reseña sea Google. Calidad excelente y servicio muy bueno. La verdad que nos ha quedado una cocina y baños muy modernos y exclusivos. Recomiendo totalmente, repetiremosTrustindex verifica que la fuente original de la reseña sea Google. Realment estic molt contenta amb el servei ofert i el material. Hem posat el model serradet en dos tons de grisos i blancs i ens encanta. El servei ha estat ràpid i eficient. Ho recomano al 100%.